Gas Distribution Systems - Regulators

Gas Distribution Systems: Reliable Regulators

Hassan El Ghoul, Mechanical Solutions Engineer

A Brief Introduction to Gas Distribution Systems

Gas distribution systems are part of various applications like chemical refining facilities, medical and experimental laboratories, and manufacturing facilities in general. Those systems comprise of lines transporting the gases from their sources to point-of-use, in addition to components that regulate the flow or pressure of those gases.

In this series, we will be going over the various pre-engineered Swagelok Gas Distribution Systems, gas application considerations, best practices, and ways to optimize system safety and performance.

suggest topics for future blog posts

Pressure Control Considerations

Pressure requirements and limitations in a fluid system are often cornerstones of an efficient design. Pressure limitations are important to ensure the material integrity of the components and avoid over-pressurization, like what can happen in analyzers. The difference in the pressure exerted by the fluid on the walls across components of a system is what keeps this fluid moving. As much as this pressure is crucial, regulating it is as critical.

We will start by introducing the crucial aspects for a reliable regulator and take a closer look at its various components. In future blogs, we will examine key factors for regulator performance and dive deeper into industry-specific applications.

Historically, fluid system components have been designed to reduce, maintain, and relieve pressure. Throughout the years, component design has been enhanced for better system efficiency and reliability.

The function of components like relief valves, pressure regulators, and check valves are all pressure dependent. Improper selection of components based on size or material compatibility can jeopardize your system's health.

contact our technical team to help with safe component selection

A Tug of War: Achieving Equilibrium

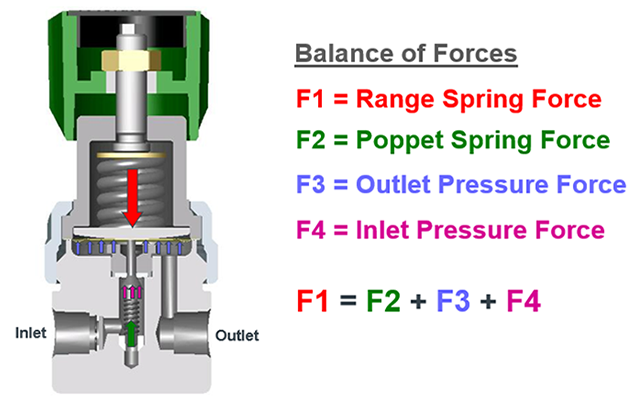

Pressure regulators are relatively autonomous components that, based on their type, achieve various pressure regulating outcomes—downstream pressure reduction or upstream pressure control. They continuously seek equilibrium of internal forces exerted by the fluid (i.e. inlet and outlet pressures) and forces exerted by the regulator's springs or fluid-filled domes. Those forces act in opposite directions like a tug of war.

Pressure regulator design has a role in achieving equilibrium of forces, thus ensuring a reliable outcome—a precise and relatively stable outlet pressure. Failure is translated in many ways, most commonly over-pressurization due to internal damage to diaphragms, seats, or other sections of the components.

Overview of a Pressure-Reducing Regulator

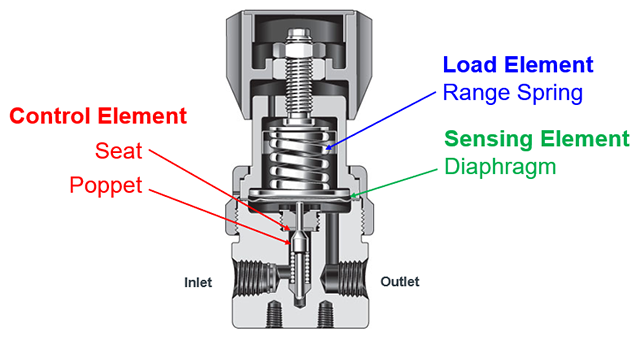

Let's take a closer look at a pressure-reducing regulator to better understand it's various components and identify key factors in reliable regulator design.

1- Seat

The seat geometry is key in allowing the poppet to adjust as flow demand changes. Any deformation, even the smallest, in the seat structure will affect the flow's behaviour, and in turn, the pressure regulation outcome.

The seat's material is thus crucial, as the presence of unexpected foreign particles in the stream is common and the chance of particles getting through a filter to the seat is possible as well. In addition to a variety of seat materials, PCTFE is one of the most common materials used in regulator seats. It achieves the sweet spot for plastic deformation resistance, temperature resistance, and enough elasticity to allow the poppet to seal against the seat when necessary; although the regulator is not to be used as a shut-off device.

One of the adverse effects of seat damage is creep, an undesired increase of the outlet pressure with time and at a set pressure point. It is caused by the damage of the seat due to the presence of process abrasive particles coming in contact with the seat at high flows. It allows flow to leak through and provoke the equilibrium of forces, thus inducing the regulator to raise its pressure. We will be talking about creep in more detail in future blog posts.

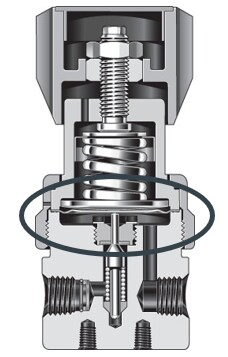

2- Sensing Element Design: Structure and Material

Depending on the desired control range, a diaphragm or piston are commonly used as sensing elements—the components that sense the outlet pressure and feed back to the control element (springs most commonly).

2.1- Diaphragm

The diaphragm is convoluted for a higher surface area and higher sensitivity. The convolutions increase the cycle life of the regulator by reducing its movement, thus decreasing the fatigue yielding stresses on it.

A thick diaphragm will be less sensitive to pressure changes and will add material cost, and a thin diaphragm is susceptible to rupture with higher or sudden pressure changes.

In addition to elastomers and PTFE, Alloy X-750 (Inconel) is commonly used in diaphragms for its chemical resistance when subjected to various fluids.

2.2- Piston

High pressure applications require sensing elements that are less sensitive to damage. Pistons rely greatly on geometry, rather than thickness, to respond to pressure changes. They are less sensitive to high resolution pressure gradients, yet can withstand relatively high pressures (greater than 500 psig).

Stainless steel is commonly used to construct pistons, given its strength and relatively good chemical compatibility with a wide range of fluids.

Pistons adjust by sliding up and down, therefore O-rings and lubrication are required. Despite the need for additional components, it is preferable to use pistons in hydrogen applications, as they do not suffer from embrittlement failure that may occur in metal diaphragms.

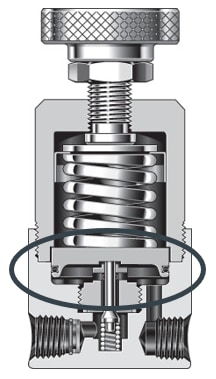

3- Loading Element Design: Structure and Material

Springs are common loading elements used in both pressure-reducing and back-pressure regulators. They are in a dynamic state, adjusting to pressure changes sensed by the diaphragm or piston.

When flow increases, the pressure differential across the orifice increases leading to a decrease in the force exerted by the control element (balance of forces). To allow more flow, the orifice must open, which causes a relaxing in the spring, and therefore a reduction in outlet pressure.

Springs are characterized by their stiffness, represented by the spring constant (k), and by their stroke length. Those parameters affect how the regulator behaves with changes in flow demand.

Droop occurs when the outlet pressure decreases with increasing flow. It all ties back to the balance of forces, as explained earlier. Droop is an undesired effect and can be resisted through improvement of the spring design. Choosing a spring with a low stiffness constant and a longer stroke improves the droop on regulators, which is generally achieved through the use of a much longer spring. Better yet, eliminate the spring and replace it with a filled dome-loaded regulator that exerts the control element force using a dome gas pressure. This type of regulator is proven to be more effective in battling the effects of droop.

This blog was an introduction to crucial aspects of a reliable regulator. Subsequent blogs in this series will take a deeper dive into those aspects, focusing on regulator performance, and touch on other application specific pressure regulators like tank-blanketing regulators and changeover regulators.

Have more questions about regulators?

Regulator Basics Tech Talk

Session Objectives:- Explain the difference between a valve and regulator

- Understand regulator terminology

- Differentiate components within a regulator

- Recognize performance attributes of a regulator

Our Subject Matter Experts provide a 45-minute technical overview with 15 minutes of Q&A throughout the session.

sign up for a regulator tech talk

learn about our tech talk program and watch more on demand webinars

Need help with a specific application?

Swagelok Central Ontario | Atlantic Canada's Virtual Round Table connects you with our local subject matter experts.

sign up for a virtual round table

We look forward to sharing more knowledge with you. To stay up to date on our latest blog posts, please subscribe at the link below.