Multihead Hydraulic Swaging Unit

Swaging Made Simple: The Multihead Hydraulic Swaging Unit (MHSU)

Braden Coombs, Associate Solutions Engineer-in-Training

Overview

Swagelok puts at their customer’s disposal a multitude of tools and equipment to support the efficient, safe, and reliable connection of Swagelok components as part of their fluid systems. For smaller bore applications (< 1’’/25 mm), it generally suffices to perform manual swaging action without the aid of specialty equipment, as outlined in the following tube fitting installation, MS-13-151. However, for larger bore applications (> 1’’/25 mm), it becomes more challenging to swage ferrules onto tubing with basic hand tools. To address this pain point when making up large bore fittings, Swagelok created the Multihead Hydraulic Swaging Unit (MHSU) that is capable of pre-swaging >1"/25 mm-sized fittings with ease.

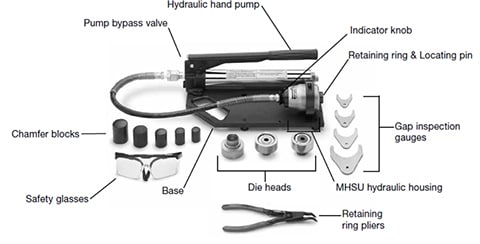

All the Tools You Need in One Handy Kit

One of the key advantages of the MHSU is that they are available in kits containing all the necessary tools needed to complete the pre-swaging process safely and with maximum reliability. Every kit includes the following:

- Safety Glasses

- Hydraulic Hand Pump (with Base if ordered)

- Pump Bypass Valve

- Indicator knob

- Hydraulic Housing

- Hydraulic Hose (2 ft/0.6 m up to 1’’/25 mm, and 6 ft/1.8 m for 1’’/25 mm and over)

- Retaining ring & locating pin

- Retaining ring pliers

- Chamfer blocks (only up to 1’’/25 mm)

- Die heads (Up to 2’’/50 mm)

- Gap Inspection Gauges

- Operating instructions

- Rugged Plastic Carrying Case

Figure 1 - Basic Components of the MHSU Kit

Kits are available in two sizes, giving customers a variety of swaging options for projects that may have different specifications on tubing and fittings sizes:

- MHSU used to pre-swage ferrules onto tubing to 1’’/or 25mm, and,

- MHSU used to pre-swage ferrules onto tubing of over 1’’/25 mm, and up to 2’’/50 mm.

Using tubing below the recommended thickness for operation in the MHSU presents obstruction potential between tubing and the die head. Before proceeding, refer to the following:

Technical Information, including Recommended Minimum Wall Thickness of Tubing.

Detailed and Straightforward Operating Instructions

To maximize swaging success, a complete instruction guide is provided to users in the MHSU kit. You can also refer to this manual here, MS-12-37. The MHSU is a simple, yet robust tool to use in pre-swaging applications. To achieve proper fitting performance, ensure that the following best practices/steps are followed and always refer to Swagelok documentation for full details:

(A) Preparation Work

1. Cut and deburr tooling to ensure a proper fit within both the swaging unit and accompanying accessories, such as the chamfer blocks. Using Swagelok tube cutters and deburring tools would facilitate this step.

2. If swaging to a tube of 1’’/25 mm or less, insert the tube into the chamfer block of the same size and strike – this ensures unobstructed entry into the die of the unit when it comes time to swage.

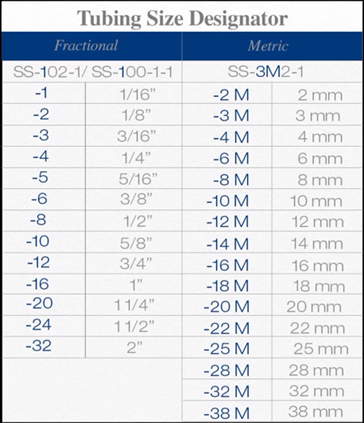

3. Before swaging, always ensure the proper die head size is inserted into the swaging unit; refer to Table 3 below for appropriate sizing. The retaining ring must be taken out and replaced if a die size change is required. Do so with the pliers provided in the unit kit.

Table 1 - Die head designator to tubing size for MHSU use (fractional/metric).

4. Before inserting a die head, check that the inner portion of the die head travels within the external portion – this acts as a quality check during the swaging process. The die will fit within the internal groove of the MHSU head, allowing the user to gently rotate the die head inward to fit. Reinstall the retaining ring.

5. Now that the die head has been appropriately selected and inserted into the MHSU head, focus on the prepared tube and fitting. Insert the tubing, then back the nut off the tubing, keeping the ferrules intact on the tube portion.

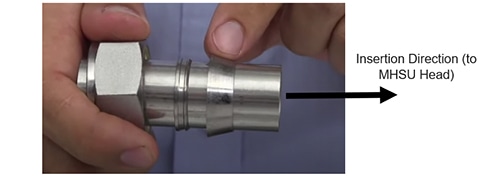

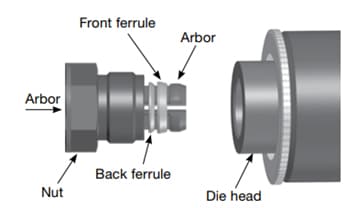

6. Inspect the orientation of the ferrules; ensure they are directed towards the tube end to be placed in the MHSU head, as per the figure below:

Figure 2 - Correct ferrule alignment towards MHSU head.

(B) Swaging

7. Insert the fitting as oriented above into the MHSU, closing the nut to the finger tight position. Push the indicator knob (on back of the MHSU head) forward until it is flush with the back of the MHSU housing (see figure below):

Figure 3 - Two -step process to ensure indicator knob is engaged prior to pumping.

8. At this point, check the bypass valve. If the bypass valve is open upon receiving the MHSU kit, tighten the valve (moving clockwise) until it stops. Pump the bypass valve using the pump lever with the fitting engaged until the knob indicator retracts to the previous ‘unflushed position’ at the back of the MHSU head.

Once the indicator knob retracts from the MHSU head during pumping, do not finish the last stroke. This could affect fitting performance, as well as present a hazard to the operator.

9. Mark circumferentially on the tubing at the back of the nut before unthreading and opening the bypass valve. This is necessary as a quality control step (see Pull Up & Verification stages below).

10. Then, open the bypass valve again (counterclockwise turning) for at least a half turn to its original position.

(C) Pull Up & Verification

11. Unthread the Swagelok nut, and rock back and forth (do not rotate) the tube out of the MHSU head.

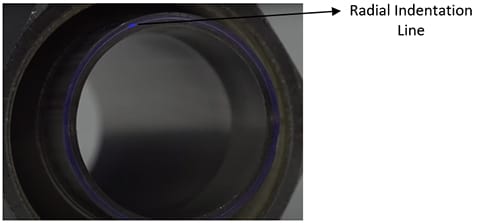

12. Inspect the swaging action – there should be a radial die indentation on the face of the tubing, see Figure 4 below.

Figure 4 - Indentation along the circumference of the tube face.

If no indentation line is visible, the pre-swaged tubing should not be used. This implies improper functionality of the MHSU and could considerably alter fitting performance/safety.

13. Begin the final stage of fitting makeup. Insert the tubing inside the fitting body and turn the nut to the finger-tight position, The line marked on the tubing near the end of the nut should be visible; retighten to the point where it is visible if it cannot be seen through finger tightening.

14. Mark the nut at the six o’clock position, hold the fitting body with a pipe wrench firmly, and tighten the nut ½ turn (if tubing is over 1’’), otherwise, refer to the tubing installation guide for required turns, MS-13-151.

15. Use the properly sized gap gauge to inspect fitting makeup after tightening. If the gap gauge enters, the nut requires additional tightening, see Figure 5 below for the visual verification.

Figure 5 - Gap Inspection Visual Check.

At this point, the fitting has been reliably swaged and is ready to be installed. This simple procedure is repeatable across a wide range of tubing sizes.

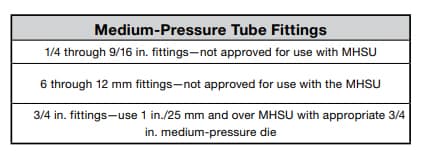

Fitting Types

In addition to pre-swaging standard gaugeable tube fittings, it is possible to pre-swage Swagelok’s medium pressure (FK) fittings of various materials (316 Stainless Steel (SS), Alloy 2507 Super Duplex, Alloy 625, etc.):

(A) 316 SS & Alloy 625:

Additionally, a specialty 1’’ fitting MHSU, the 16FK MHSU, is available for pre-swaging 1’’ FK fittings. The operation/instructional guide follows a very similar process as the standard gaugeable fittings guide and is available here, MS-CRD-0250.

Figure 6 - Orientation of FK fitting into 16FK MHSU Die.

The MHSU cannot be used for pre-swaging ½’’ and under medium-pressure fittings.

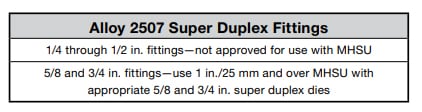

(B) Alloy 2507 Super Duplex:

Similar to the Stainless steel and Alloy 400 fittings, it is necessary to order the specialty 1’’ and over MHSU unit to pre-swage 1’’ Alloy 2507 Super Duplex fittings. Refer to the ordering information in the Gaugeable Tube Fittings and Adapter Fittings catalog, MS-01-140.

Generally, 316FK, Alloy 625, and Alloy 2507 Super Duplex specialty fittings are used in demanding applications in oil and gas, which include but are not limited to:

- Wellhead control panels

- Hydraulic control panels

- Grease injector units

- Blowout preventers

- Chemical injection skids

Applications for these fittings continue to grow, as there has been increased usage in fields such as industrial R&D and Hydrogen systems. Their reconfigurability, enhanced high pressure performance, and high vibration resistance make them a suitable fitting in varied applications. The suite of medium to high pressure fittings are designed with reference to ASME standards (B31.3, B31.3 Chapter IX), but can also be fabricated and treated to be compliant with the following standards:

- NACE MR0175/ISO

- NORSOK M-630 and M-650

- API-6A

Key Features and Advantages

Overall, the MHSU provides safe, reliable, pre-swaging which enables strong fitting performance in a broad range of applications. The list below highlights the key advantages of Swagelok’s MHSU:

1) Reliability |

Easy to follow, standardized approach, with robust, proven tooling used to pre-swage ferrules. Connections and installations are repeatable, regardless of operator skill. |

2) Maximizes Performance

|

Puts no initial strain or unwanted torque on nut, fitting body, and threads. Ensures a strong, leak tight connection. |

3) Configurable |

Available for use across a wide range of fitting types, materials, and applications – including low to high pressure. |

4) Efficient |

Reduces the time necessary to pre-swage and then install fittings into fluid systems. Operator error is mitigated due to the repeatable, concise instructions provided. |

5) Simple |

All equipment is prepared in a kit, with an instruction manual. Swagelok associates are available to support any issues. |

Rent or Buy

The MHSU is available for either rental (paid for at a daily, weekly, or monthly frequency), or outright purchase.

This provides clients with the flexibility to use an MHSU for project specific jobs as needed, or, to have a reliable tool available if they regularly work with large bore fluid systems.

Swagelok simplifies ownership by providing a myriad of accessories for the MHSU, including:

- Tooling Kits – Available with varied sizes of chamfer blocks, die heads, and gap inspection gauges. These items are all replaceable, refer to the gaugeable tube fittings catalogue.

- Support Base – Can be added to your MHSU tooling kit; use the ‘-B’ designator.

- Retaining Ring & Pliers – Replacements are available with the purchase/rental of the MHSU unit

The ordering specification between renting and purchasing the MHSU varies, particularly across different Swagelok Sales & Service Centres.

Please contact your Local Sales & Service Centre for ordering information for the MHSU most suitable for your applications.

Troubleshooting & Customer Support

While the MHSU is a robust and reliable tool, there is always potential to run into challenges during your pre-swaging activities. For this reason, Swagelok has compiled a list of some of the most common sources of error/technical difficulties that can arise during the swaging process. Refer to some of the common troubleshooting tips for both swaging of standard gaugeable tube fittings as well as medium pressure fittings.

Contact us for Further technical training and support

Important References

Please refer to the following documents that were mentioned in this blog post for more detailed information into Swagelok products as they relate to the MHSU operation:

Swagelok Gaugeable Tube Fittings and Adapter Fittings catalog, MS-01-140

Swagelok Tubing Data catalog, MS-01-107

Swagelok Medium- and High-Pressure Fittings, Tubing, Valves, and Accessories, MS-02-472

Swagelok Medium- and High-Pressure Fittings and Adapters—Alloy Materials, MS-02-474

Swagelok Multihead Hydraulic Swaging Unit (MHSU) Setup and Operating Instructions, MS-12-37

Swagelok Multihead Hydraulic Swaging Unit (MHSU): 16FK Operating Instructions, MS-CRD-0250

subscribe to the swage talks blog