Mastering Tube Bending

Mastering Tube Bending: A Comprehensive Overview of Swagelok's Hand Tube Bender, Benchtop Tube Bender, and Electric Tube Bender

Mitchel Hardy, Associate Solutions Engineer

Brandon Van Bilsen, Engineering Technical Specialist

The Need for Tube Bending

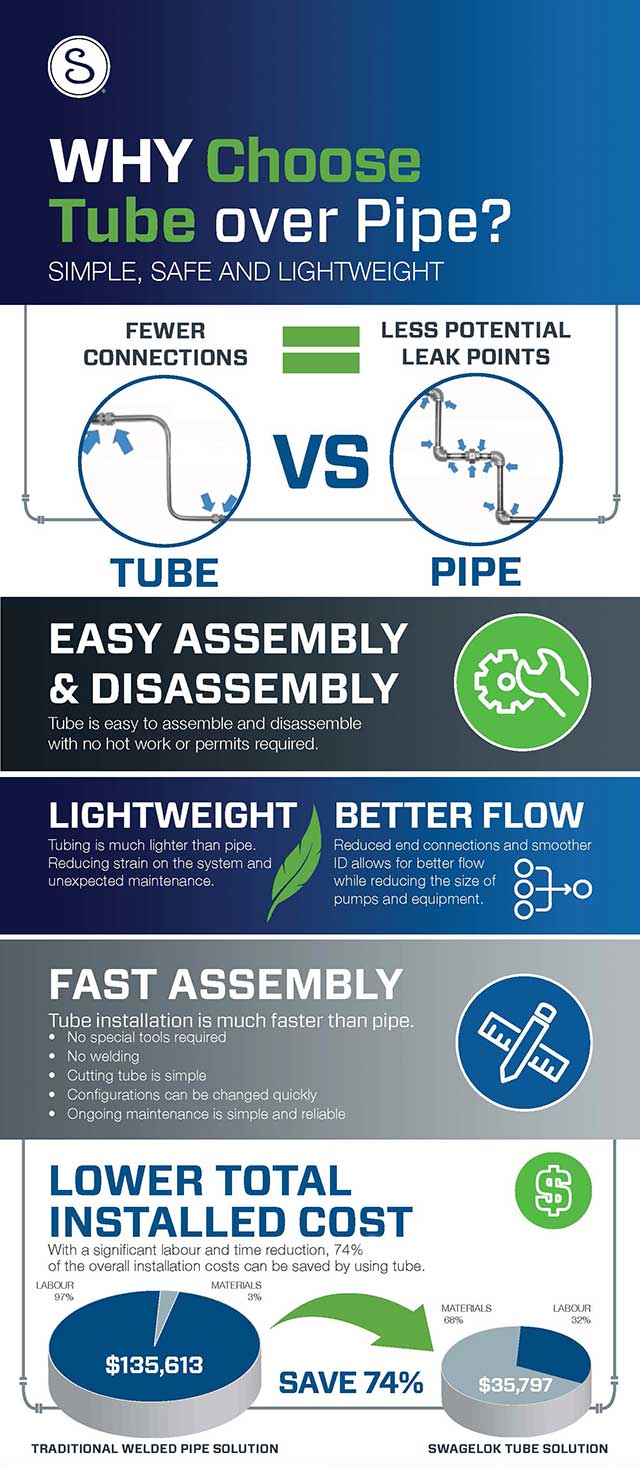

Tube bending is a critical process used across various industries to create fluid flow systems, construct pipelines, and develop complex structures. Industrial fluid systems typically operate under high pressures and can contain thousands of connections or leak points. The failure of just one joint can have catastrophic consequences. For several decades, tubing and tube fittings have gained popularity across industries where maximum leak integrity, high performance, and ease of installation and maintenance are crucial. The advantages of using tubing over piping such as strength to weight ratio, fewer connections, vibration resistance, and energy conservation, are especially designed for critical applications.

Tube Bending Options

With the demand for efficiency and precision on the rise, bending tubes manually is no longer the only option. Advancements in technology have led to the development of innovative tools, including Swagelok's Hand Tube Bender, Benchtop Tube Bender, and Electric Tube Bender. In this blog post, we'll explore these three bending solutions and their unique advantages.

1. Swagelok® Hand Tube Bender: The Trusty Workhorse

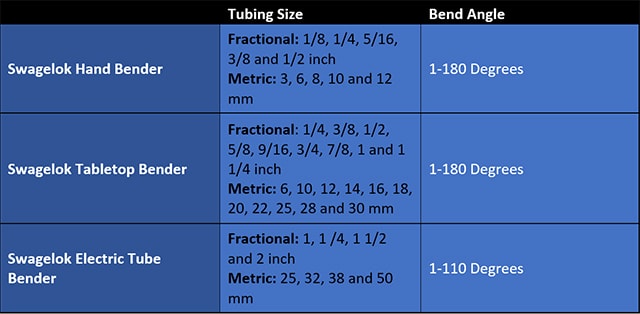

Swagelok's Hand Tube Bender is a classic and reliable tool that has been used for decades in various industries. This manual bender provides a straightforward and cost-effective method for bending small-diameter tubing (1/8-1/2 inch or 3-12 mm) in a wide range of materials, with precision and accuracy. Here's what makes it stand out:

- Portability and Ease of Use: The Swagelok Hand Tube Bender is compact and easy to carry, making it suitable for on-site projects and repairs. Its simple design allows both novice and experienced operators to achieve accurate bends effortlessly.

- Consistent Bends: This hand tool offers the advantage of consistent bending radius and angle, ensuring that each bend meets the required specifications. This uniformity is crucial in maintaining fluid flow and structural integrity.

- Cost-Effectiveness: For low-volume tube bending needs, the Swagelok Hand Tube Bender is an economical choice. It eliminates the need for power sources or complex setups, making it a cost-efficient option for small-scale applications.

2. Swagelok® Bench Top Benders: Precision and Convenience at Your Fingertips

This tool brings precision and convenience to the forefront, making it a popular choice for both small-scale applications and larger production environments. The benchtop bender allows for manual bending of medium-sized tubing (1/4-1 1/4 inch) safely and efficiently. Let's explore the features and advantages of the Swagelok Benchtop Bender:

- Rugged and Lightweight: These tube benders make it simple to create consistent tube bends in a range of configurations, allowing you to expedite installation.

- Quality and Reliability: Swagelok is renowned for manufacturing high-quality products, and the Benchtop Bender is no exception. It is built to withstand the rigors of industrial use and deliver reliable performance over an extended period. Investing in a Swagelok Benchtop Bender ensures that you have a dependable tool that can handle your tube bending needs for years to come while maintaining high quality standards.

3. Swagelok® Electric Tube Bender: Embracing Precision and Automation

As industries evolve and seek higher productivity levels, the Electric Tube Bender has emerged as a valuable solution. This semi-automatic machine combines precision with automation to streamline the bending process. Key features include:

- Enhanced Precision: Electric Tube Benders are designed to handle complex bends, in larger tubing sizes (1-2 inches) with a high degree of accuracy. Programmable controls allow operators to set precise bending angles, reducing the likelihood of errors and ensuring consistent results.

NOTE: The electric tube bender has a bending range of 1 degree to 110 degrees and can bend tubing in 1 degree increments. As safety is of utmost concern, all electric tube benders come with an emergency stop button and a circuit breaker. The electric tube bender weighs about 420 LB (191KG). The tubing is held in a die roller and held in place with a tube clamp. The die rotates and bends the tube to the desired bend angle.

- Increased Productivity: With automation, operators can bend tubes faster, reducing production time and increasing overall output. This is particularly beneficial for projects requiring large quantities of bent tubes. This bender can save time and money on a project that requires a lot of twists and turns. If operated properly, the bender will output hundreds of consistent, quality, precise bends in a day.

- Suitable for Various Materials: Electric Tube Benders are versatile and can handle various tube materials, such as stainless steel, copper, aluminum, and more. This versatility makes them an attractive choice for diverse industries.

NOTE: All tubing should be free of scratches, dents, abrasions and checked for other factors to make sure its suitable for bending. Bends can range for different sizes of tubing from 1 inch all the way up to 2 inches or 25 mm to 50 mm OD in variety of wall thicknesses. Carbon steel tubing should be fully annealed, seamless or welded and drawn, meeting ASTM A269, ASTM A213, EN-ISO-1127, or equivalent specification with a hardness of 80 HRB, HV(VPN) 180 or less.

In Summary, whether you choose the traditional Swagelok Hand Tube Bender, the precision-oriented Benchtop Bender, or the powerful Electric Tube Bender, each option has its place in the world of tube bending. The selection depends on the project's scale, complexity, and required output. As technology continues to advance, we can expect further improvements in tube bending tools, catering to the ever-growing needs of industries around the globe. If you are interested in having the opportunity to use some of our benders, please contact your local Swagelok representative. Whether you are looking to rent, buy or acquire training, we would be happy to help you reach your goals.

contact us for more information on Swagelok Tube Benders

We look forward to sharing more knowledge with you. To stay up to date on our latest blog posts, please subscribe at the link below.