Custom Fabrication and Assembly Solutions

Custom Fabrication and Assembly Solutions

Fabricating a custom fluid system can be a challenge for many companies because of lack of resources, time and personnel to complete a job. We can help you.

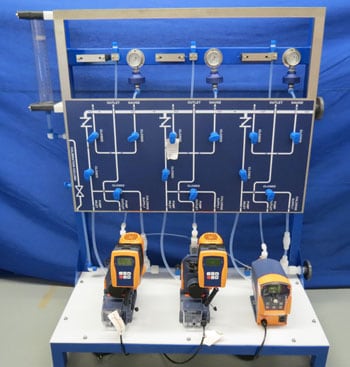

Reduce your planning, assembly and purchasing costs by taking advantage of our custom fabrication and assembly solutions for OEM, process, instrumentation, maintenance, and a wide variety of fluid system applications. Swagelok Ontario's complete assembled solutions include 3D models, drawings, and BOMs. We also source components from other manufacturers, reducing the number of suppliers and SKUs. Our finished assemblies lower your costs by reducing your: In-house component inspections, QA effort, component handling, rework & scrap, and assembly time.

From simple sub-assemblies to complex fabrications, we recognize that every situation is unique and customize options and alternatives to fulfill your needs. Want to learn more? Schedule a tour of our Custom Solutions facility.

Our capabilities include:

- 3D CAD modeling;

- Component sourcing;

- Project management & document control;

- Prototype development;

- Component assembly & testing;

- Accurate tube bending up to 2 inch diameter;

- Tube fitting installation;

- Orbital welding; and

- Custom coiling

Our Certifications include:

- TSSA Certificates of Authorization (C of A):

o To fabricate welded and non-welded category D and H fittings in accordance with CSA B51.

o To fabricate pressure piping in accordance with CSA B51, ASME B31.3 for process piping.

o To fabricate pressure piping in accordance with CSA B51, ASME B31.1 for power piping.

o To fabricate pressure piping in accordance with CSA-Z-7396 nonflammable Medical Gas Piping. - Swagelok Quality System (SQS), a business management system designed to help authorized Swagelok sales and service centres systematically manage and improve processes throughout their supply chain.